The insertion efficiency of an optical signal into a photonic-crystal fiber is increased when the central air hole is filled with a metal wire.

© 2012 A*STAR Singapore Institute of Manufacturing Technology

Optical fibers are rapidly replacing electrical wires as the primary medium for sending digital information over long distances. Without suffering from interference, pulses of light travelling along these thin strands of glass can carry more data than electrical signals. However, getting light into fibers can be difficult, and this inefficiency limits the total strength of the optical signal received at the far end. The solution may be a fiber structure that was recently proposed by Xia Yu at the A*STAR Singapore Institute of Manufacturing Technology and co‐workers which uses a metal core to reduce these aptly named insertion losses. “Our compact fiber-based coupler device is able to couple with light more efficiently and faster than conventional devices,” says Yu.

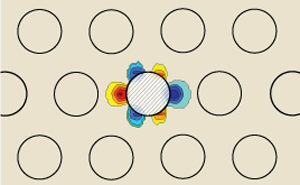

Yu and her team based the design of their device on a new type of photonic-crystal fiber (PCF). PCFs include spaces in the glass that run along the entire length of the fiber. When examined in cross-section (see image), these ‘air holes’ have a honeycomb-like arrangement. Reflection of the incoming light at the numerous air–glass interfaces confines the light to the center of the fiber.

In a theoretical modeling study, Yu and co-workers showed that the addition of a metal wire through the center of the fiber improved device efficiency. The incoming light couples to the electrons in the metal wire, and this forms matter–light hybrid particles called surface plasmons, Yu explains.

The researchers simulated the optical confinement of infrared light in a structure with air holes 2 micrometers in diameter. They then divided the light-carrying core of the fiber with a silver wire. Their calculations indicated that the best design has a hole-to-hole distance of 4 micrometers: it enabled a coupling efficiency of nearly 82%.

Another important way to characterize fiber performance is to determine the distance light must travel along the structure before it couples properly with the fiber — the shorter the better. Compared with conventional designs, this metal-core approach enabled a one order of magnitude reduction in this coupling length.

Such a device could be used as an optical switch or to combine or separate optical signals at different wavelengths — a procedure called multiplexing — which is vital for maximizing the amount of information optical signals can carry.

“The next step is to fabricate the device,” says Yu. “The structure can be easily realized by replacing the center air hole with a metal wire during fiber production, or by pumping molten metal into the center air hole post fabrication.”

The A*STAR-affiliated researchers contributing to this research are from the Singapore Institute of Manufacturing Technology.