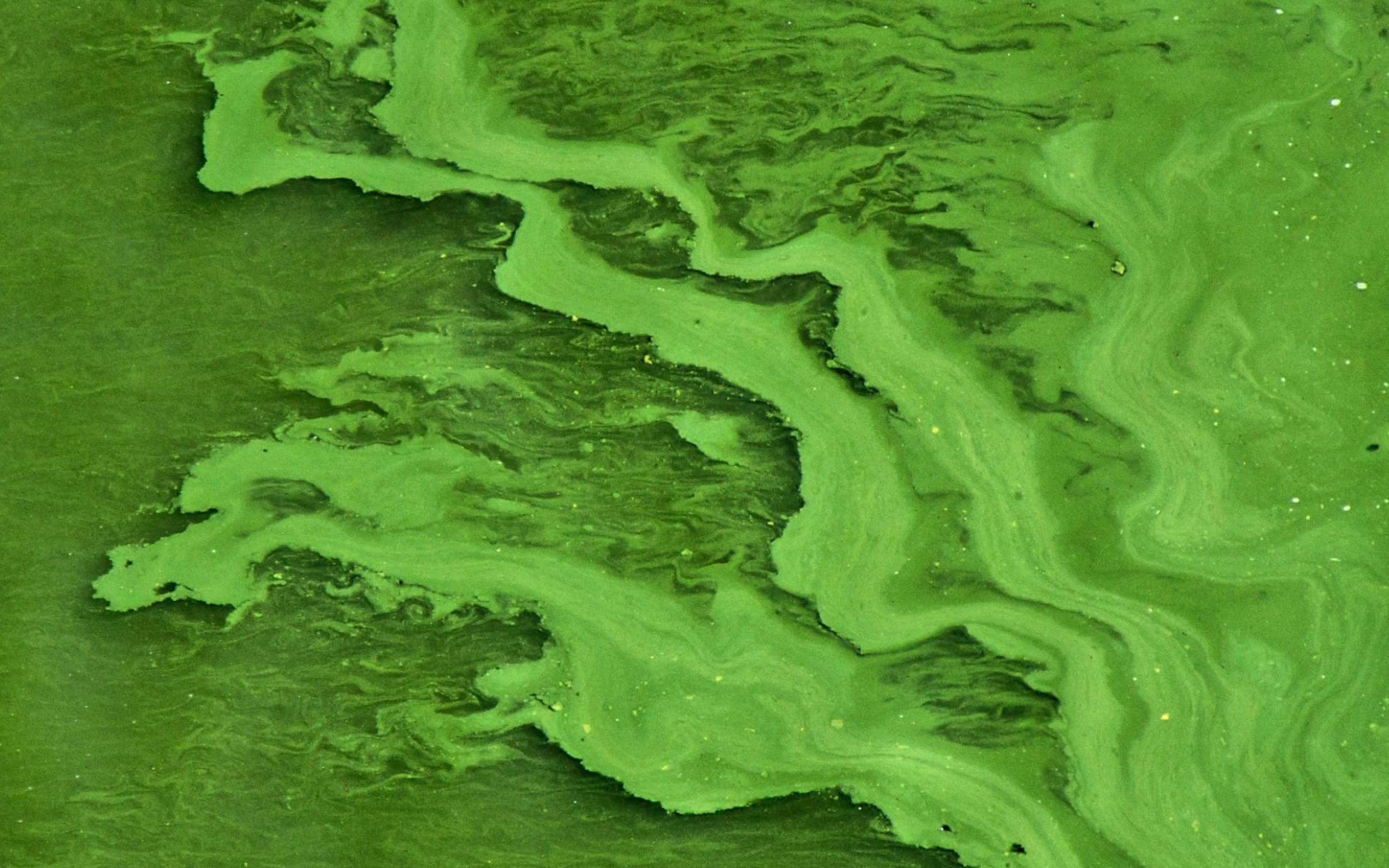

Nitrate runoff from farms and factories can pose a serious threat to aquatic life by fuelling toxic, oxygen-draining algal blooms. As nitrates break down into nitrites over time, these pollutants can further endanger human and animal health. However, some scientists are flipping the script to harness nitrate-rich wastewater as a rich source of ammonia, supplying the chemical industry and fuelling the green energy economy.

At the A*STAR Institute of Materials Research and Engineering (A*STAR IMRE), Adjunct Scientist Yanwei Lum and PhD student Jiguang Zhang are developing electrocatalytic cells for the task. These systems can use renewable electricity to drive key chemical reactions on a catalyst’s surface under mild conditions, offering greener alternatives to traditional carbon- and energy-intensive methods of producing ammonia.

Yet while copper (Cu) has been the go-to catalyst for this process, the metal often falters halfway, explained Lum.

“Nitrate is first converted to nitrite, which is then converted into ammonia. But with some catalysts such as copper, the process can halt at the nitrite step,” Lum said. “This happens when the nitrite intermediate detaches from the catalyst surface before the reaction completes.”

An alternative catalyst, oxide-derived copper (OD-Cu), has recently shown both high ammonia yields and Faradaic efficiency (FE)—a measure of how well electricity drives the target reaction—when used in ammonia production. While previous studies have suspected that OD-Cu has multiple functional sites to catalyse each step of the process, its exact mechanisms remained unclear.

Schematic diagram of the active sites present on copper (Cu) and oxide-derived copper (OD-Cu) catalysts for nitrate-to-ammonia conversion. Two distinct sites on OD-Cu convert nitrates to nitrites (Site A), and nitrites into ammonia (Site B), boosting its efficiency compared to Cu, where conversion can halt at the nitrite step. (Adapted from Zhang et al. 2024)

To shed light on OD-Cu’s secrets, Lum and Zhang worked with colleagues from A*STAR IMRE, the A*STAR Institute of Sustainability for Chemicals, Energy and Environment (A*STAR ISCE2) and the National University of Singapore, including A*STAR IMRE Scientist Zainal Aabdin and A*STAR ISCE2 Senior Scientist Shibo Xi.

Putting OD-Cu through a series of electron microscopes and electrochemical tests, the team found that it achieved an FE of 90.67 percent for nitrate-to-ammonia conversion. This contrasted with Cu’s FE of 67.03 percent, with the remainder diverted to nitrites. Curiously, OD-Cu performed exceptionally well with a mixed feed of equal parts nitrate and nitrite, a pattern not seen with Cu.

“This revealed that there are two types of active sites present on OD-Cu which cooperate through a relay mechanism: nitrate-to-nitrite occurs on one site, and nitrite-to-ammonia on the other,” said Zhang.

The researchers confirmed this division of labour using ATR-SEIRAS, an infrared spectroscopy technique that monitors reaction intermediates in real time using radioactively-labelled molecules. For further validation, they built a mathematical model of OD-Cu reflecting two separate reaction sites, then conducted simulations with varying nitrate-to-nitrite ratios. The model mirrored their experimental results, supporting the catalytic tag team’s role in OD-Cu’s high efficiency.

Encouraged by their findings, the team aims to apply a similar strategy to develop high-performance electrocatalysts that produce urea from nitrate feedstocks.

The A*STAR-affiliated researchers contributing to this research are the A*STAR Institute of Materials Research and Engineering (A*STAR IMRE) and the A*STAR Institute of Sustainability for Chemicals, Energy and Environment (A*STAR ISCE2).