Soft sensors that boast the ‘human touch’ have long been the holy grail for makers of soft electronics, robotics and healthcare devices. However, the challenge is more than capturing a squeeze or a stretch; like our skin, such sensors should ideally be versatile enough to simultaneously detect not just the presence of pressure, but its degree, location and even the type of object creating it.

A team of researchers including Junhua Kong, a Senior Scientist at the A*STAR Institute of Materials Research and Engineering (A*STAR IMRE), has recently invented a new hydrogel-based sensor to do the job. “We aimed to create something that was as human-like as possible. Something simple, sensitive and multi-functional, yet not reliant on expensive materials or complex testing methods,” said Kong.

Drawing inspiration from nature, Kong and colleagues from A*STAR IMRE, the A*STAR Institute of High Performance Computing (A*STAR IHPC) and Nanyang Technological University’s School of Materials Science and Engineering, Singapore, fabricated a polymeric hydrogel made of polyvinyl alcohol reinforced with cellulose nanofibres (CNF) to mimic the elasticity of sponges and the structural toughness of wood. A freeze-casting technique gave the material long, one-way channels that allow water and ions to flow freely.

“The hydrogel works like a basic resistive sensor—it’s essentially a ‘noodle’ connected to two electrodes,” Kong explained. “When touched or stimulated, it responds by changing its electrical properties; it ‘feels’ the touch electronically.”

Infused with an ionic solution and coated with a thin sodium alginate film, the sensor functions using alternating current impedance measurement: a method that reads changes in a material’s electrical resistance without the drawbacks of traditional direct current systems, such as electrode corrosion.

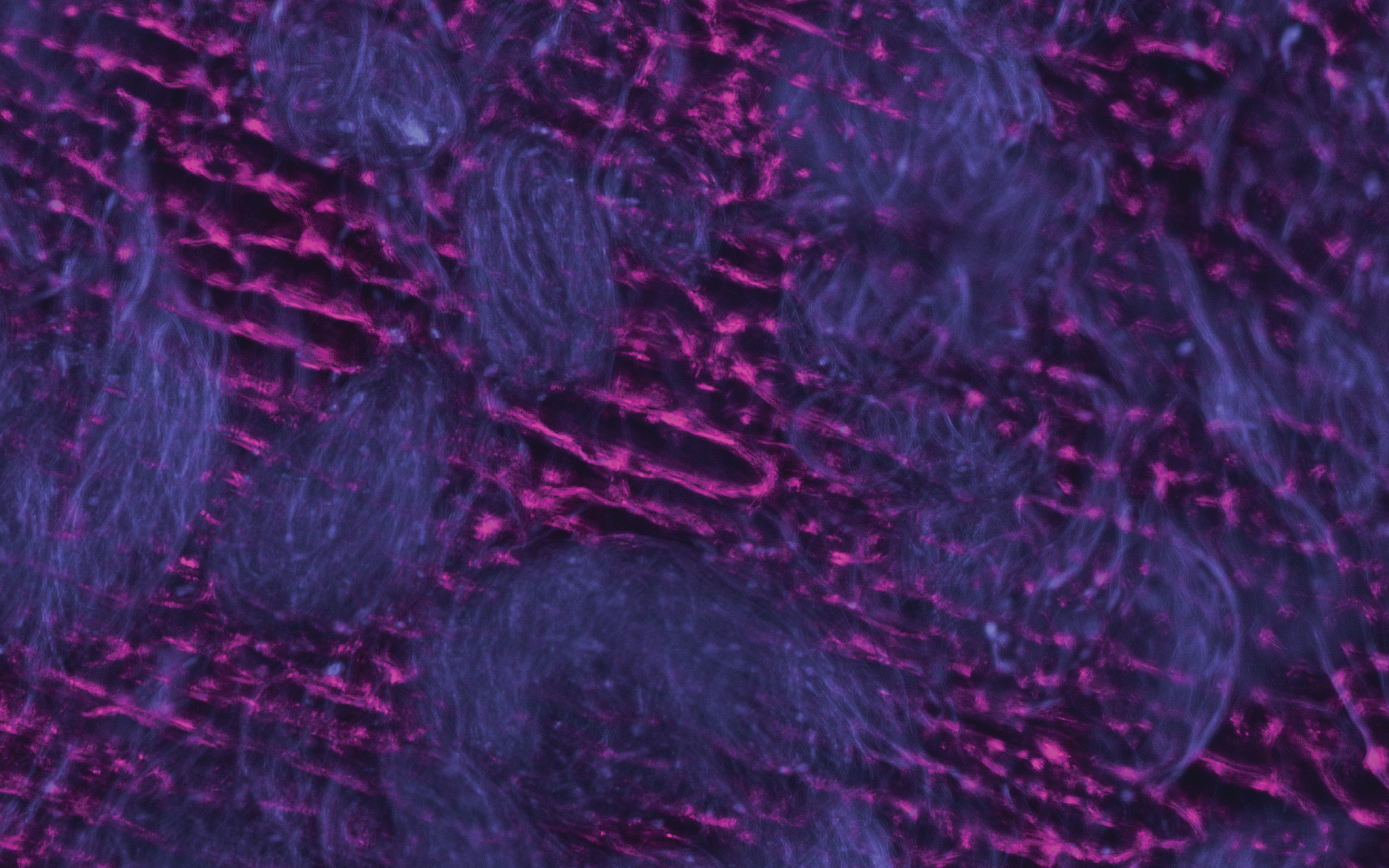

Design, fabrication and structural study of the sponge hydrogel. (a) Schematic illustration of the fabrication process. (b) Cross-sectional view of an as-fabricated sponge hydrogel through scanning electron microscopy. (c) Cross-sectional views of the hydrogel when wet, showing directional PVA walls (top) and randomly-distributed CNF tangles (bottom), through confocal laser scanning microscopy (CLSM). (d) Stacked CLSM images showing both PVA and CNF structures. (e) Micro-CT scan of the hydrogel when dry, showing aligned channels. (f) Schematic of the hydrogel’s internal structure when infused with salt solution.

Xiangyu Duan / Nanyang Technological University / A*STAR Institute of Materials Research and Engineering

Using their simple sensor format, the team demonstrated three distinct capabilities: measuring pressure via deformation, pinpointing the location of a touch and identifying different materials based on their unique impedance signatures. They then combined these functions into several practical devices, including a motion-sensitive interface for minimally-mobile patients; a 3D touchpad; and a robotic gripper that distinguished between metal, plastic and organic items.

“What surprised us was how much information we could extract from a single point of touch,” Kong said. “With such a simple setup, we picked up differences in impedance between materials that created a rich dataset for sensing possibilities.”

The team was also surprised to discover that the hydrogel’s CNF content had tangled up in tumbleweed-like structures, causing them to act like elastic springs. “We didn’t set out to create these tangles,” said Kong, “but they turned out to be key to the hydrogel’s exceptional elasticity and recovery after being compressed.”

The hydrogel’s softness and conformability make it potentially suited to wearable health monitors and bioelectrodes. Looking ahead, the team plans to explore alternative materials to further enhance the hydrogel’s performance, as well as its applications beyond sensing, including biomedicine and energy storage.

The A*STAR-affiliated researchers contributing to this research are from the A*STAR Institute of Materials Research and Engineering (A*STAR IMRE) and the A*STAR Institute of High Performance Computing (A*STAR IHPC).