Just as gemstones require the right cut and careful polishing to reveal its brilliance, the tiny crystals at the heart of chip technologies depend upon detailed patterning during fabrication to unlock their full potential. One such material, α-phase molybdenum trioxide (α-MoO3), is under the spotlight for its ability to tune electromagnetic fields, making it valuable for nanophotonic applications such as infrared light manipulation and optical signal processing.

α-MoO3 crystals consist of layers of tightly bound atoms, with each layer held together by weak van der Waals forces. “This unique structure allows them to be exfoliated into atomically thin sheets with novel electronic, optical and mechanical properties,” explained Qian Wang, a Principal Scientist at the A*STAR Institute of Materials Research and Engineering (A*STAR IMRE).

A major obstacle in commercialising these materials, however, lies in the fabrication process. While current techniques can etch the desired intricate patterns, they also introduce artifacts to the crystals. Wang, Qiyao Liu of A*STAR IMRE, Zheng Liu of Nanyang Technological University, Singapore, and collaborators from institutes in China found a simple solution to this issue: introducing a hot water rinse after the traditional patterning step.

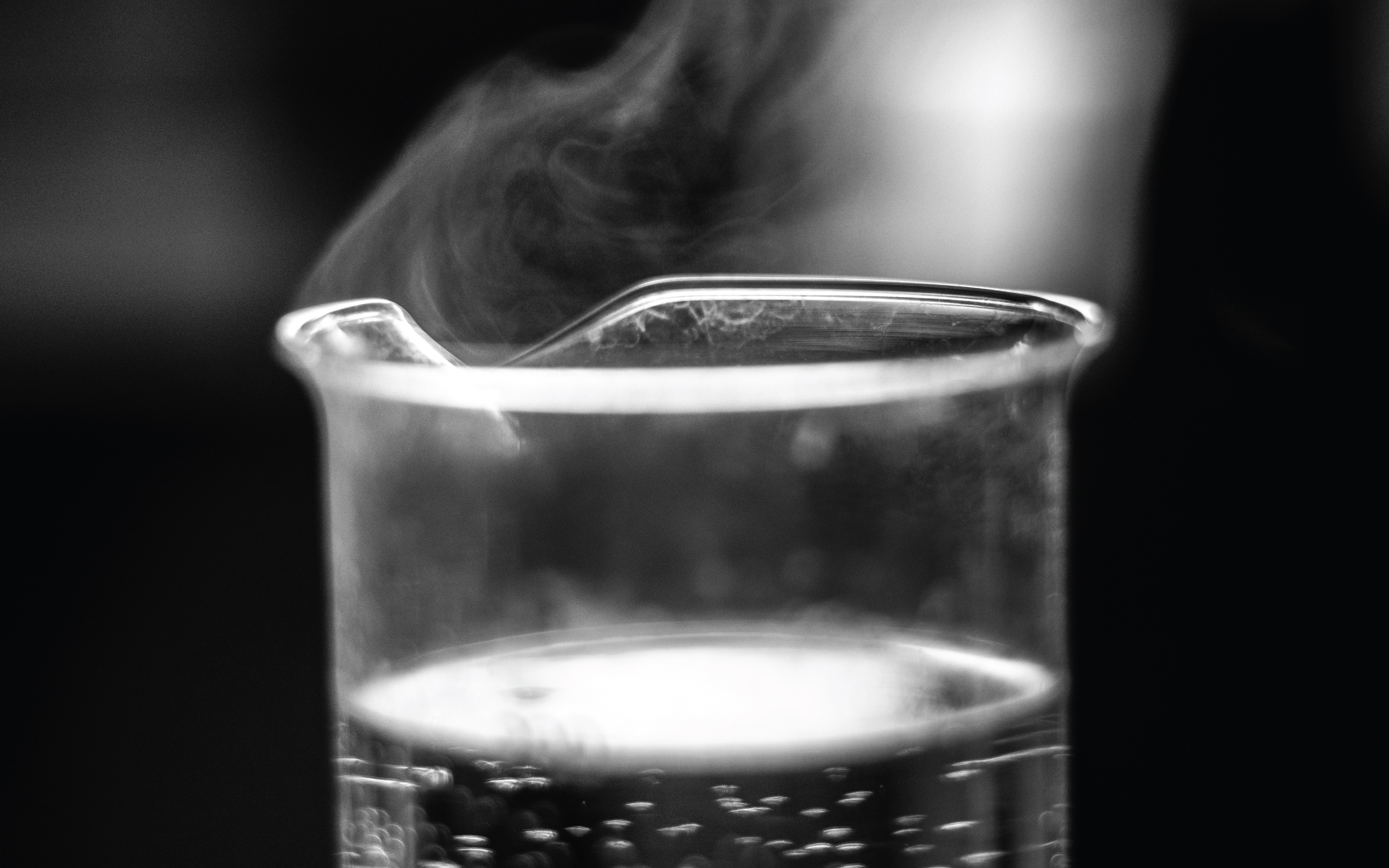

“During our attempts to transfer MoO3 flakes assisted by water vapour, we observed that the vapour caused surface smoothing with slightly enhanced optical signal,” said Wang. “We immersed the patterned sample in hot water for just one minute and, to our surprise, observed a pronounced and reproducible anisotropic etching.”

Based on this discovery, the team dug deeper to explore how hot water could be used to improve nanofabrication techniques, determining the effects of variables such as temperature and soaking time on the etching of these van der Waals materials.

In addition to smoothening out the defects during fabrication, the researchers also achieved directional control over the etching process by exploiting the difference between the weak interlayer van der Waals forces and the strong intralayer binding interactions.

“Breaking the crystal lattice in the intralayer direction exposes planes with different densities of dangling bonds,” Wang explained. “These dangling bonds influence the rate of the chemical reaction, allowing etching to proceed much faster along the intralayer and creating nanostructures with precisely aligned edges.”

Having validated their technique with a prototype, the team is optimistic that their chemical-free etching methodology can be applied to a broader range of van der Waals materials, potentially leading to the development of better nanophotonic devices.

“It paves the way for the integration of this method with scalable lithographic processes to develop large area, low-loss devices for mid-infrared nanoscale sensing and imaging applications,” Wang said.

The A*STAR-affiliated researchers contributing to this research are from the A*STAR Institute of Materials Research and Engineering (A*STAR IMRE).